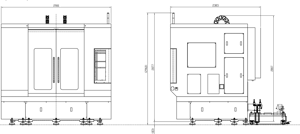

S-600D

The S‑600D is a dual‑spindle drilling center with HSK‑E25/HSK‑E32 taper and optional ultrasonics engineered for precision micro‑hole machining. It is equivalent to two machines in a single footprint, thanks to its dual‑spindle, dual‑table architecture. Its two‑head design with dual‑axis control synchronizes operations for ultra‑precise micro holes and high‑quality surface finishes, supported by a low‑centroid gantry and FEM‑optimized rigidity to minimize vibration.

HSKTaper |

8HP Spindle |

38kRPM |

Product Overview

The S-600D's two tables and dual‑axis control enable simultaneous operations with independent offsets across X1/X2, Y1/Y2, and Z, delivering high throughput in a single, compact footprint. A low‑centroid gantry and FEM‑optimized rigidity minimize vibration to maintain ultra‑precise hole quality and superior surface finishes—even in hard materials like silicon and ceramics.

Nomura DS Machines for Every Industry

CNC machines are used in nearly every application. Discover how Nomura DS machining can enhance your production and boost efficiency in your industry.

Resources |

Support |

| Get the knowledge you need to run your operation more smoothly and profitably. Access industry case studies, manuals and more. |

Keep your machine up and running with unmatched technical service and support. |

Specifications

General Info

Floor Space

114.2 x 96.5 in

Table Size

2 - 23.62 x 23.62 in

Controller

Mitsubishi M80

Tool Stations

20 x 2

Spindle

Speed

38,000 RPM plus optional RPM (40,000)

Power

8 HP

Taper

HSK-E32 - Ultrasonic

Travel

Travel (X, Y, Z)

31.5 x 23.6 x 11.8 in

Rapid Traverse

1889.7 ipm